Discussion

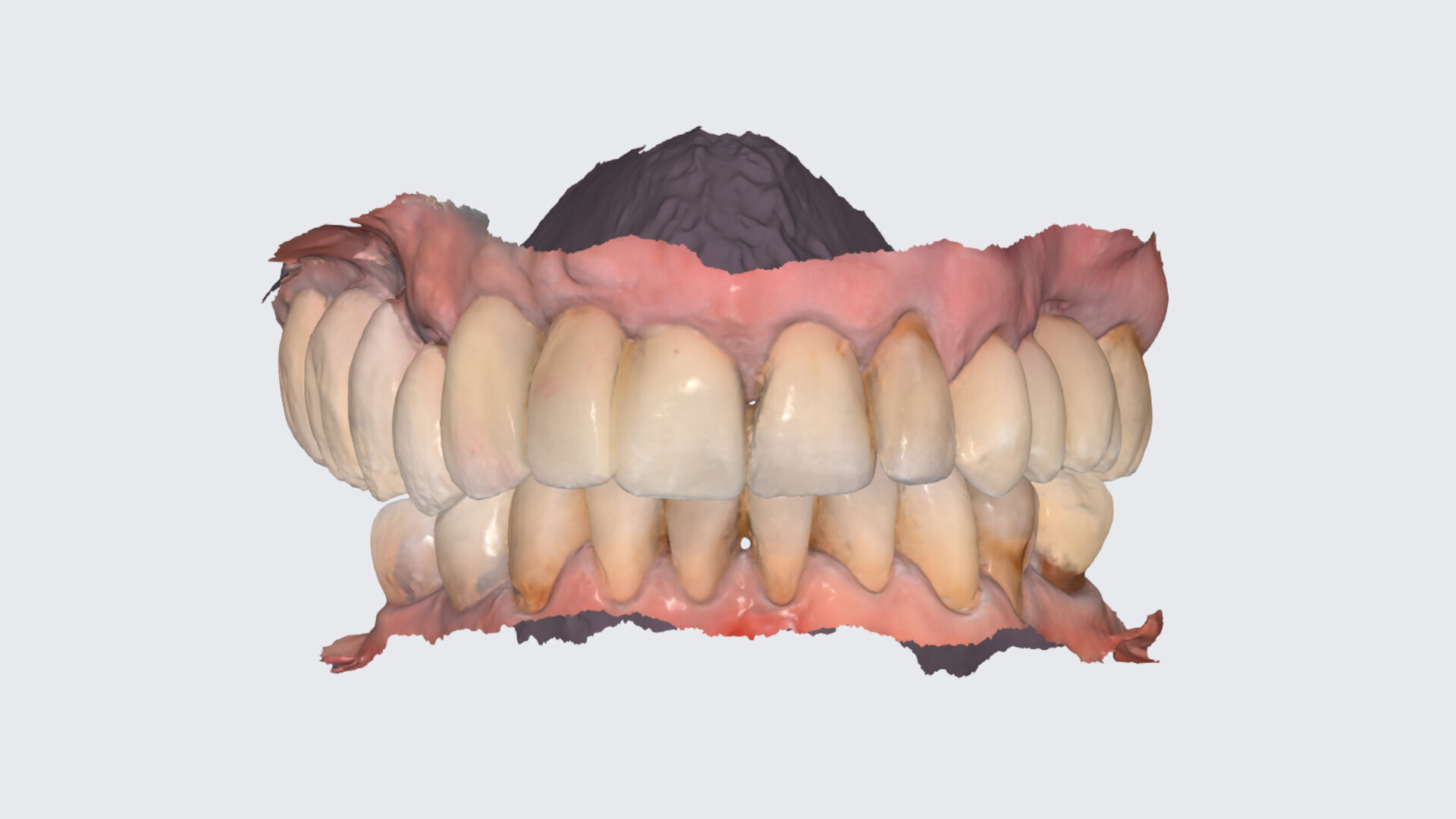

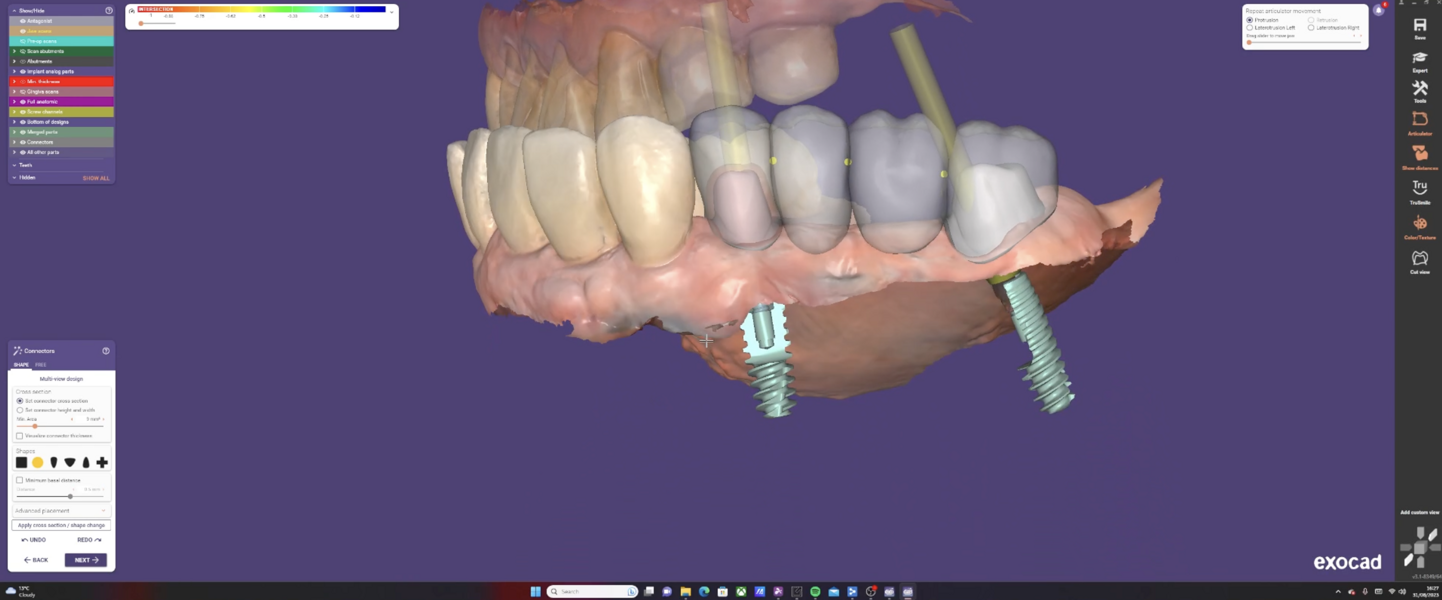

The integration of digital dentistry into clinical practice has been a transformative evolution in the field. The case presented here underscores the importance of a comprehensive digital workflow in modern implant dentistry. The use of virtual planning, guided surgery and in-house milling ensured precision and reduced the overall treatment time.

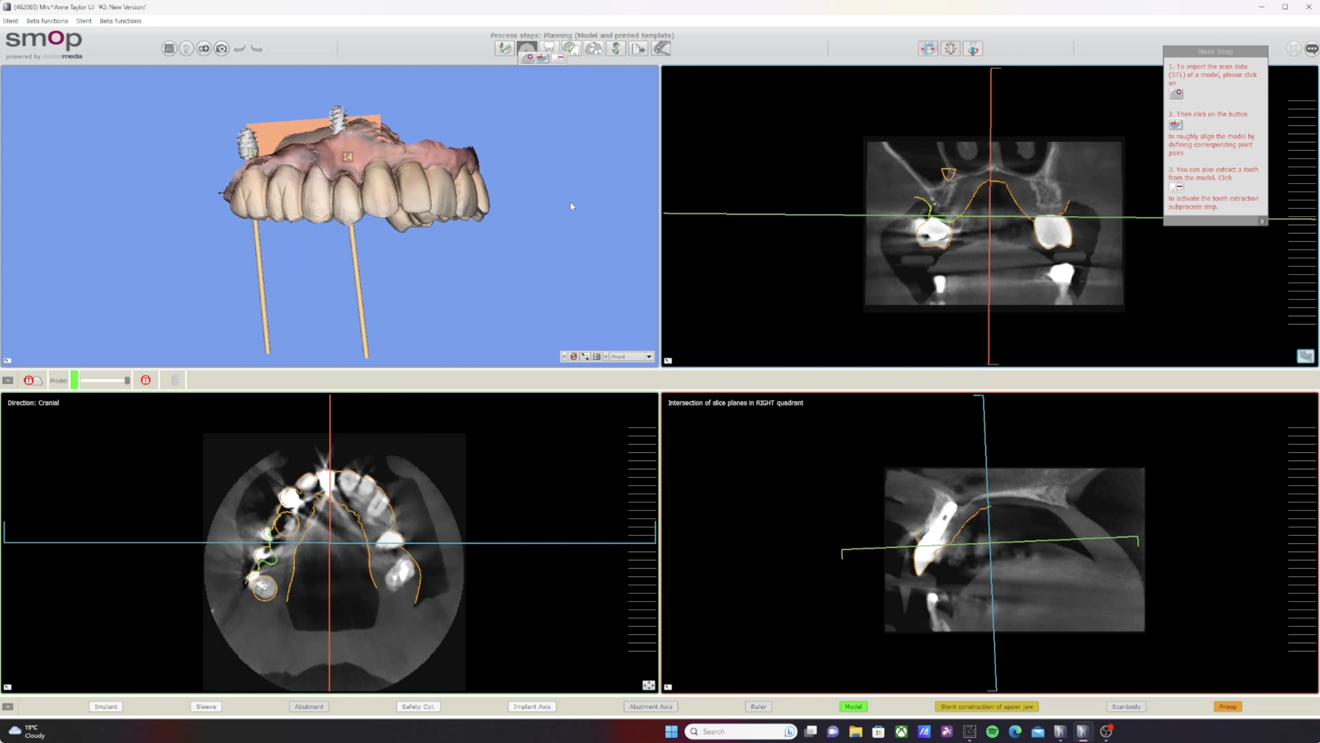

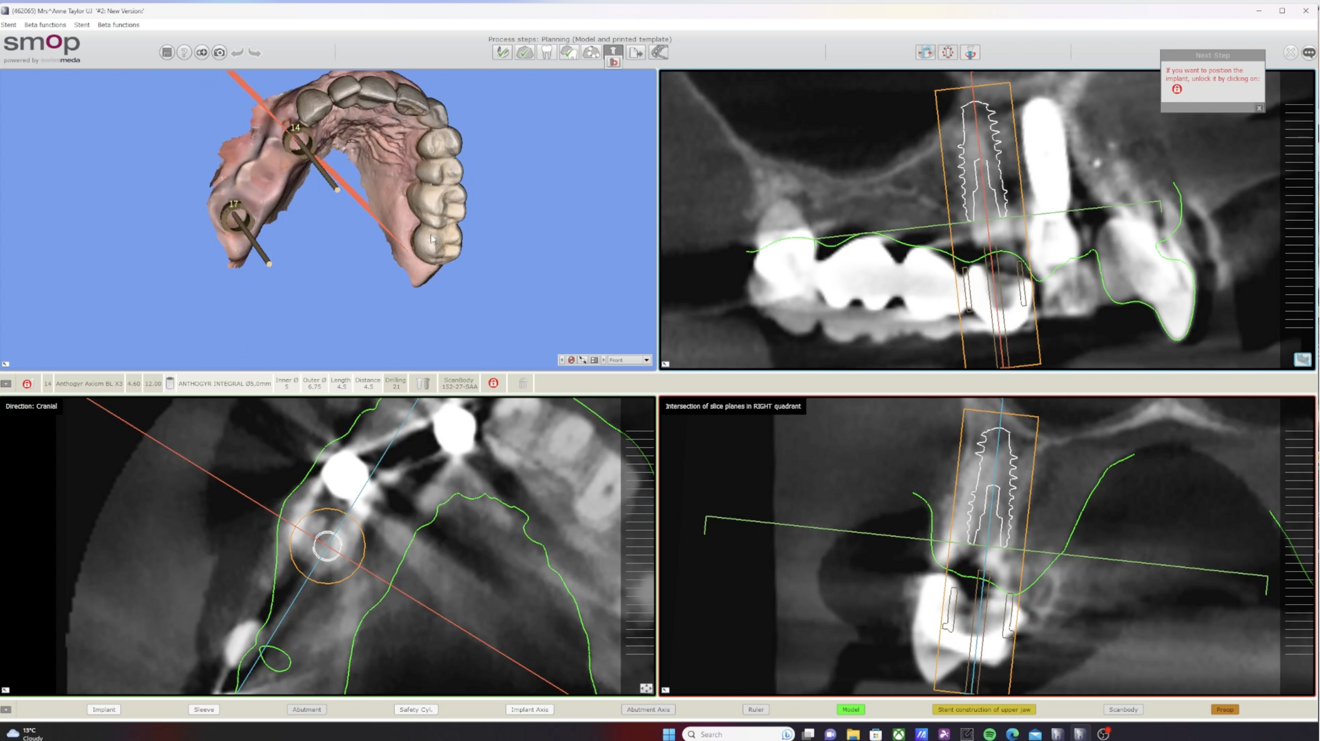

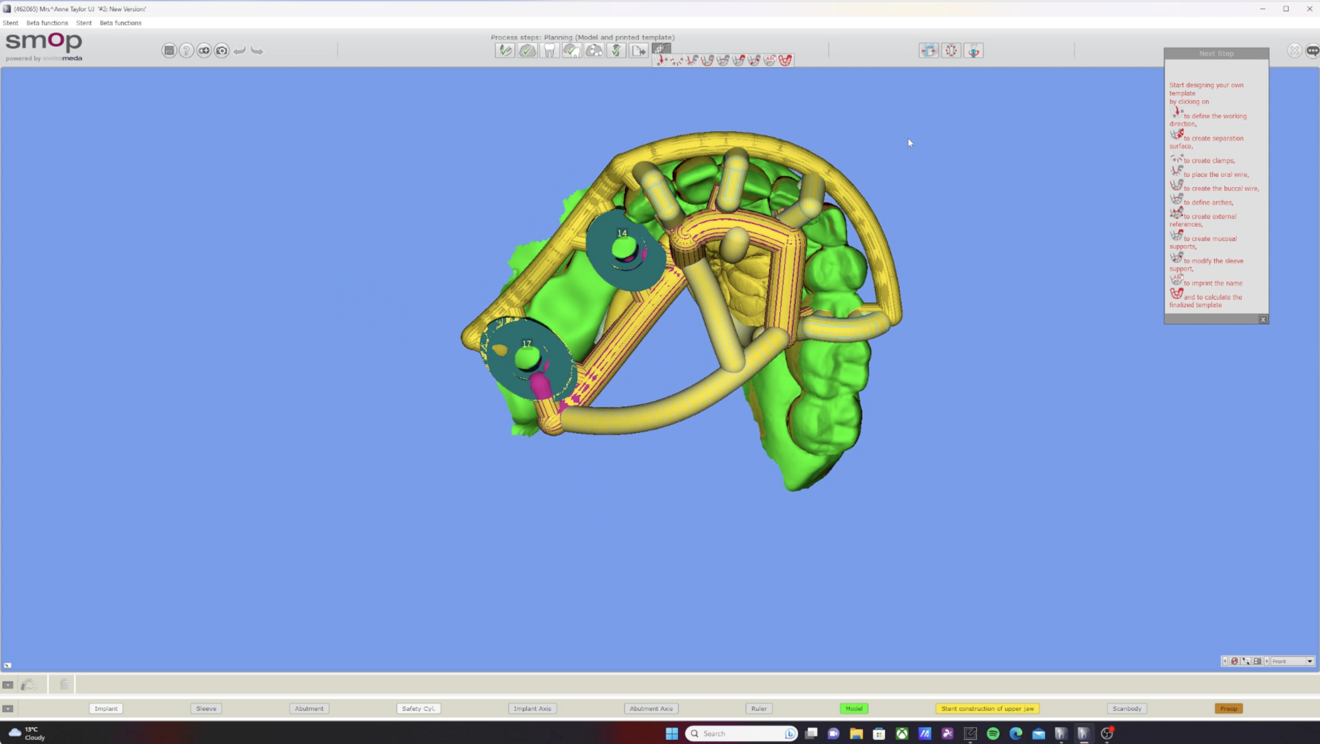

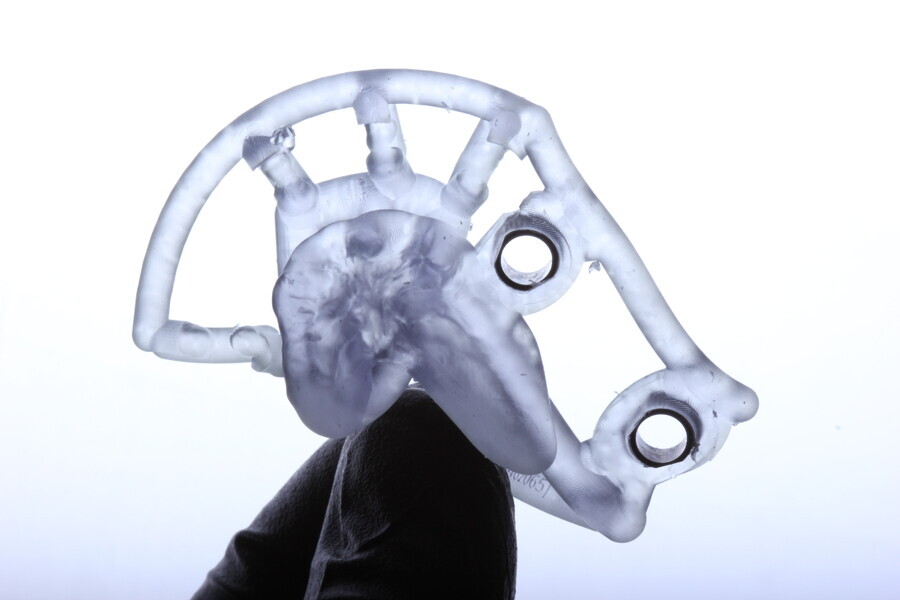

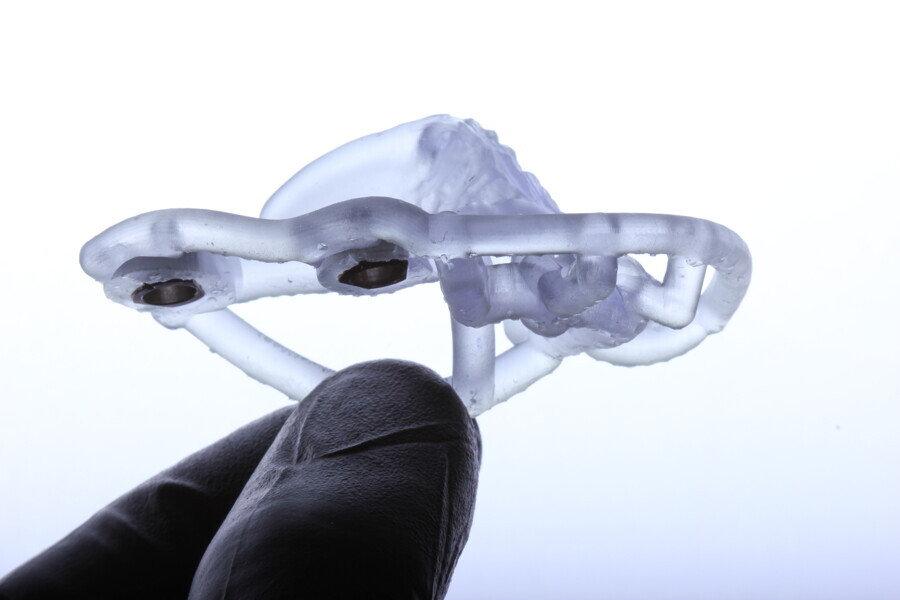

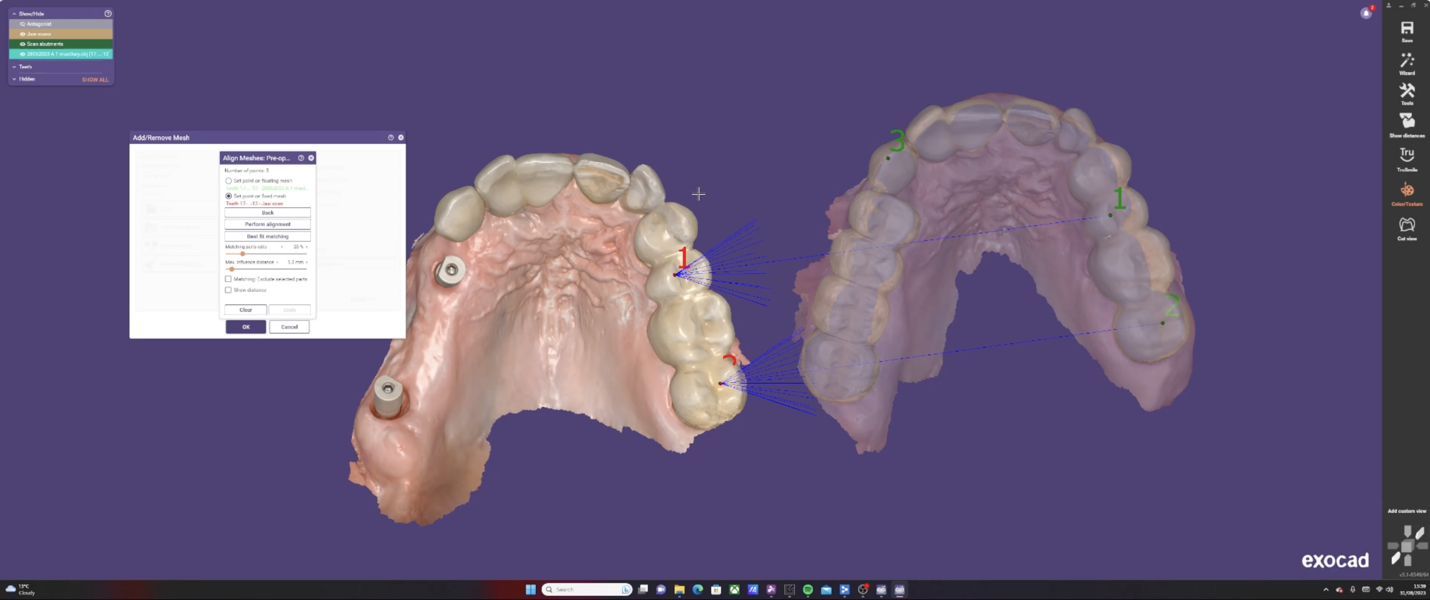

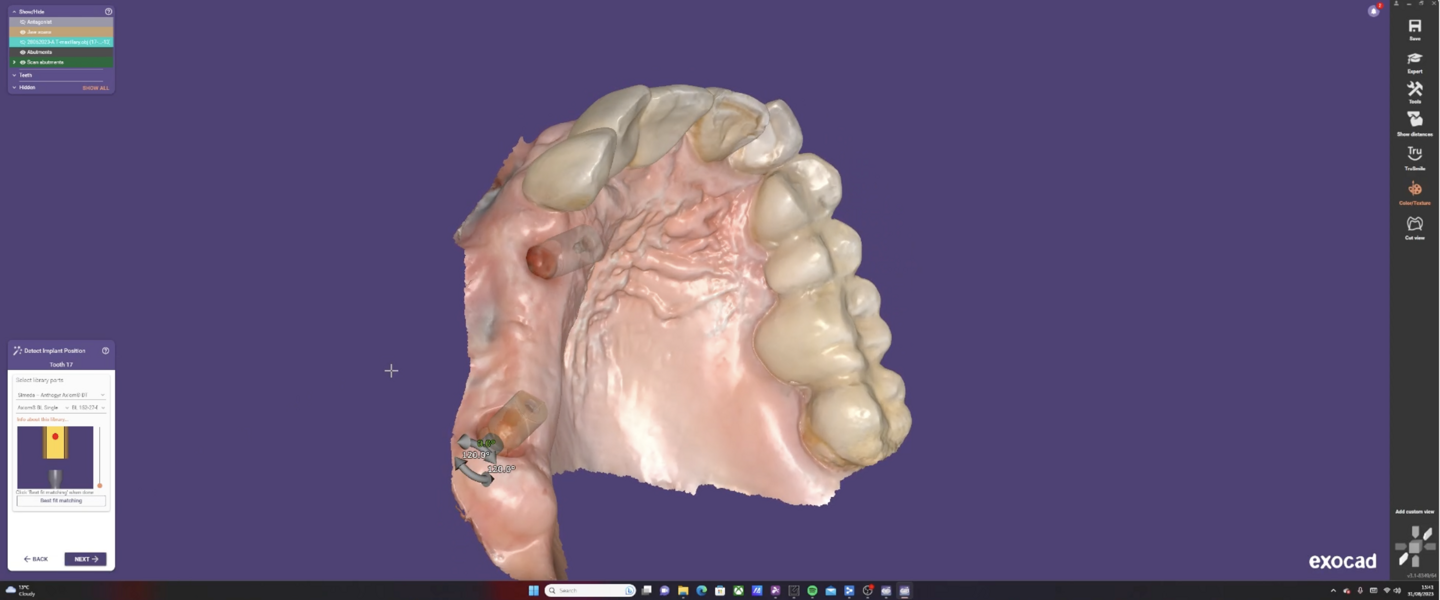

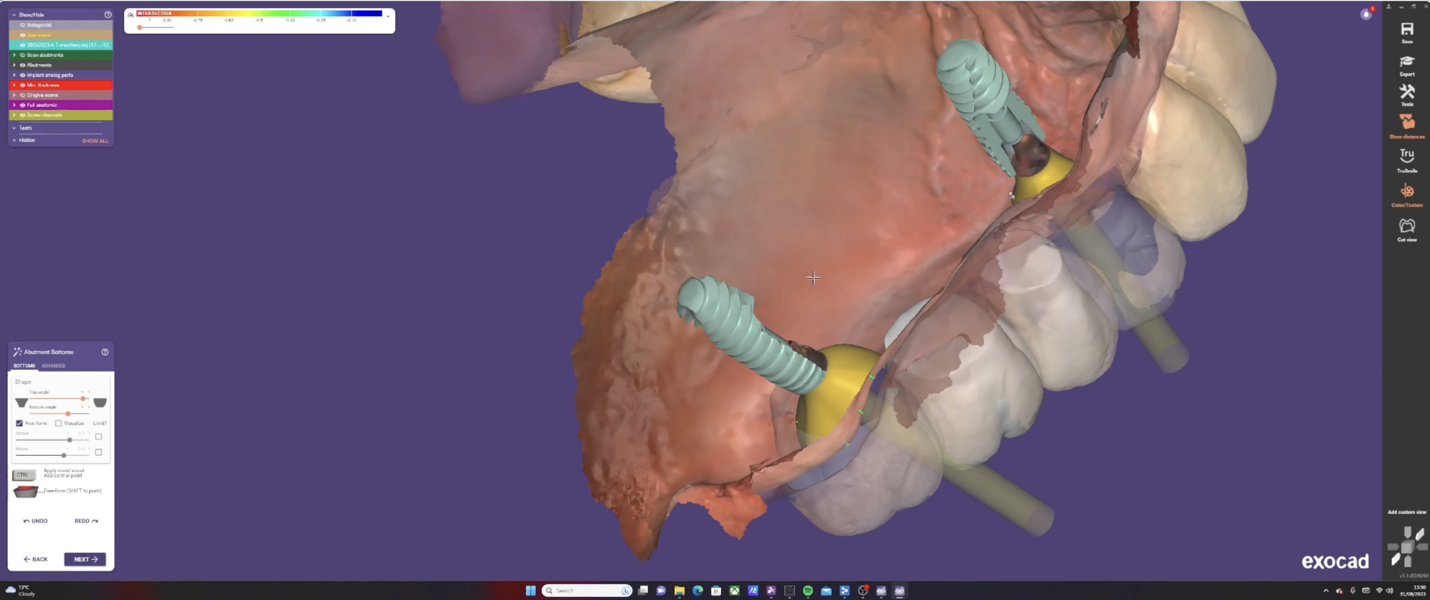

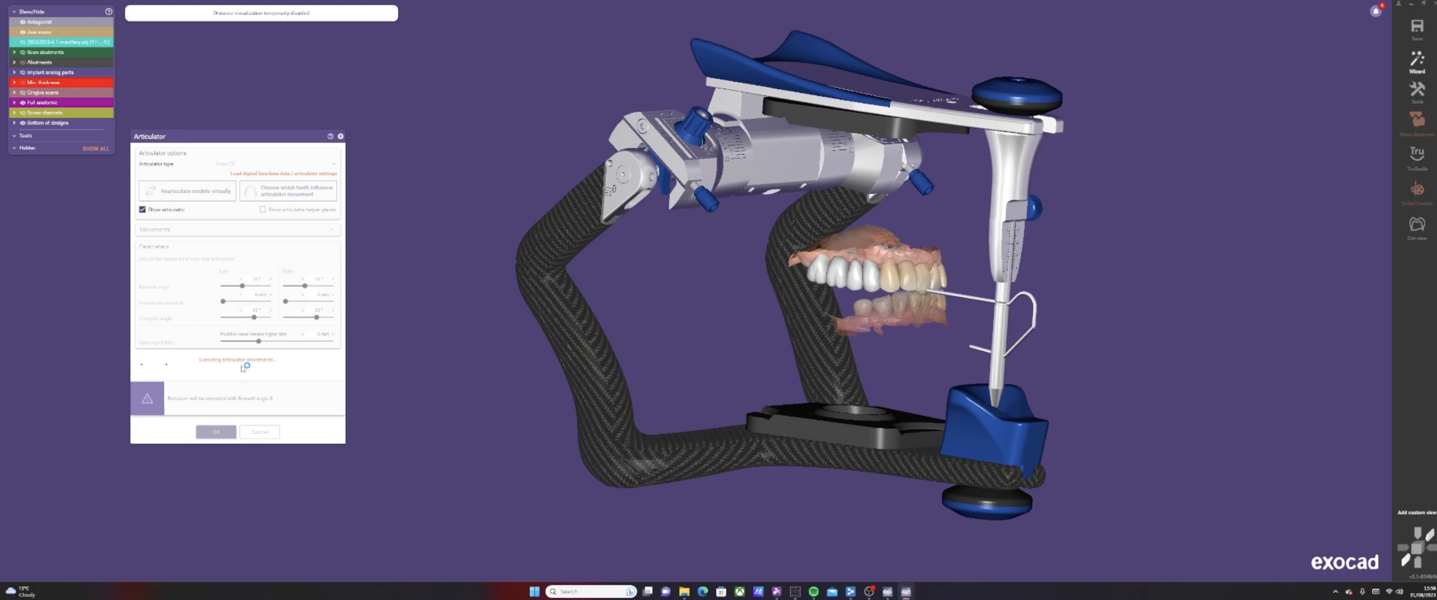

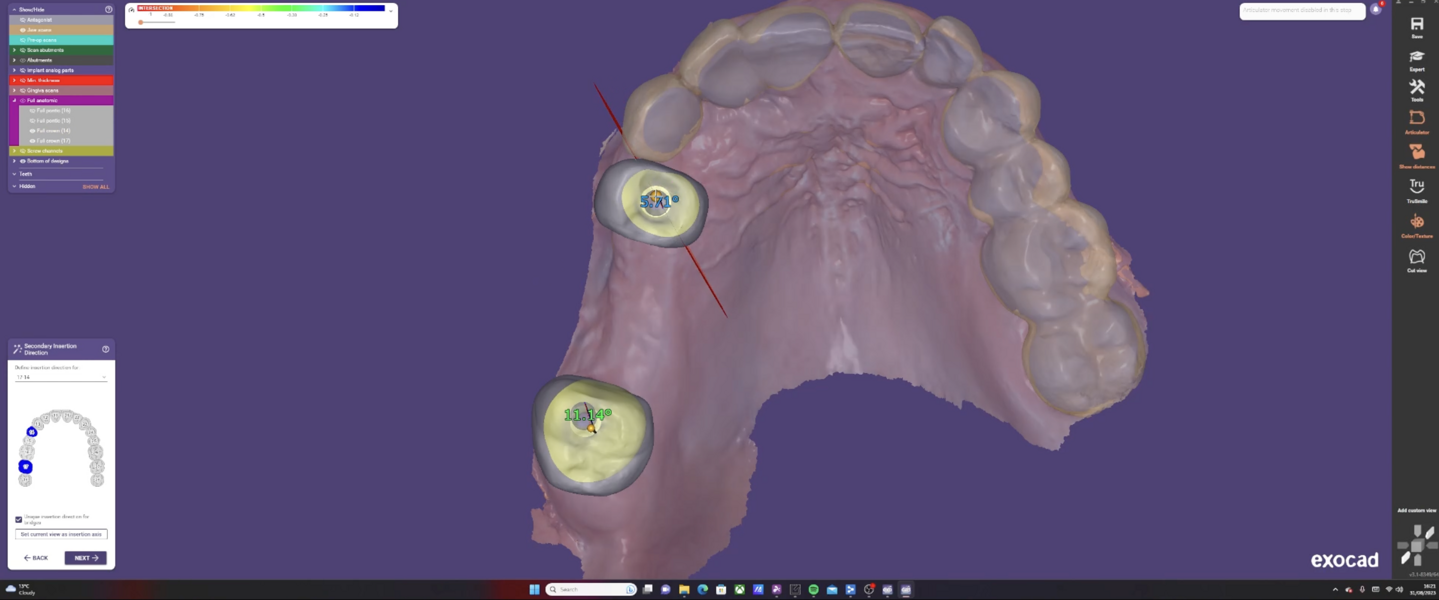

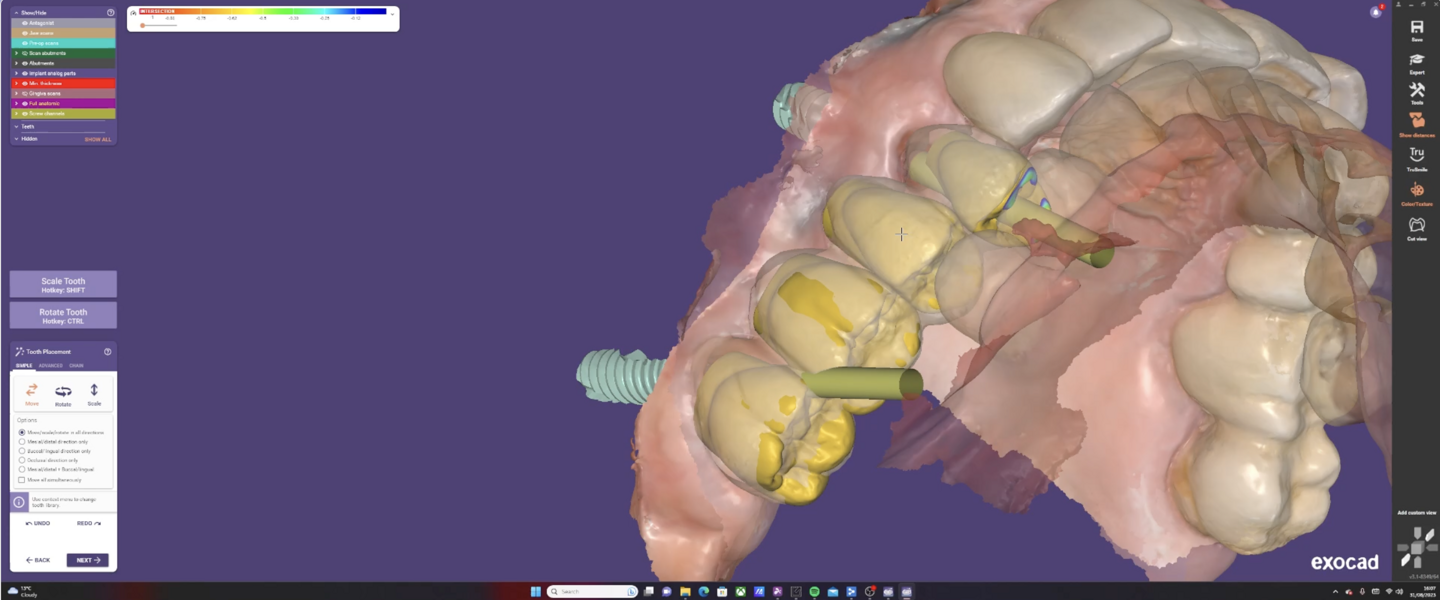

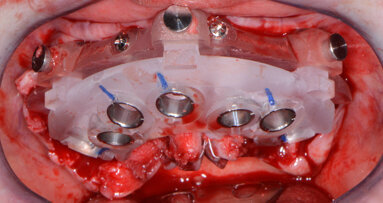

Virtual planning and guided surgery

The utilisation of virtual planning tools, such as Medit Design and SMOP, allows for a more predictable surgical outcome. Mangano et al. highlight that digital workflows, including virtual planning and guided surgery, improve the accuracy of implant placement, reduce surgical time and minimise postoperative complications.1 This precision ensures that the implant is placed in the most optimal position, reducing the risk of complications and ensuring the longevity of the implant.

Immediate implant placement

Immediate implant placement, as executed in this case, has its advantages. Chen and Buser emphasise the benefits of immediate implant placement, including reduced treatment time, preservation of soft and hard tissue, and improved aesthetic outcomes.2 This method not only speeds up the treatment process but also results in greater patient satisfaction owing to the reduced number of visits and faster recovery.

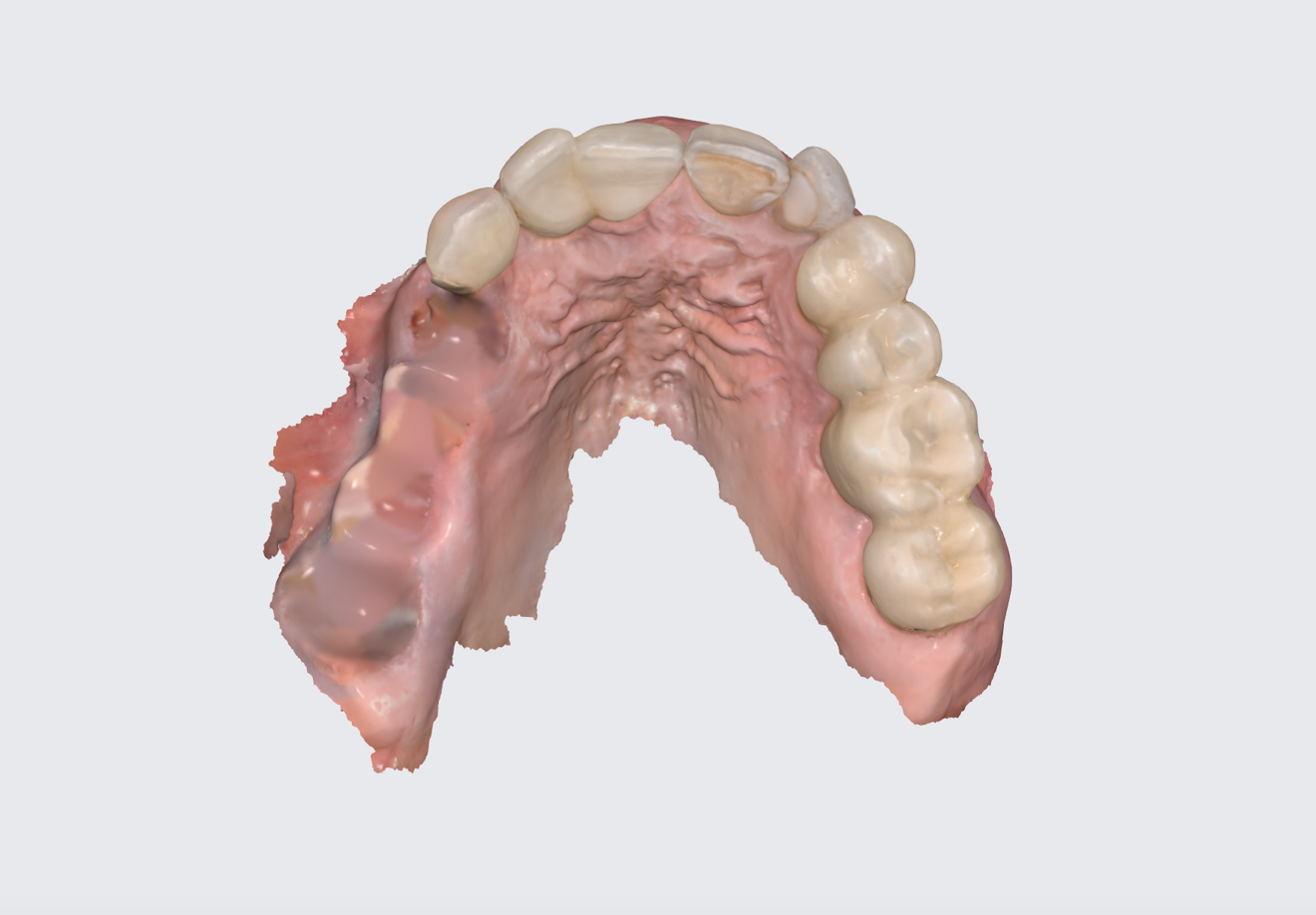

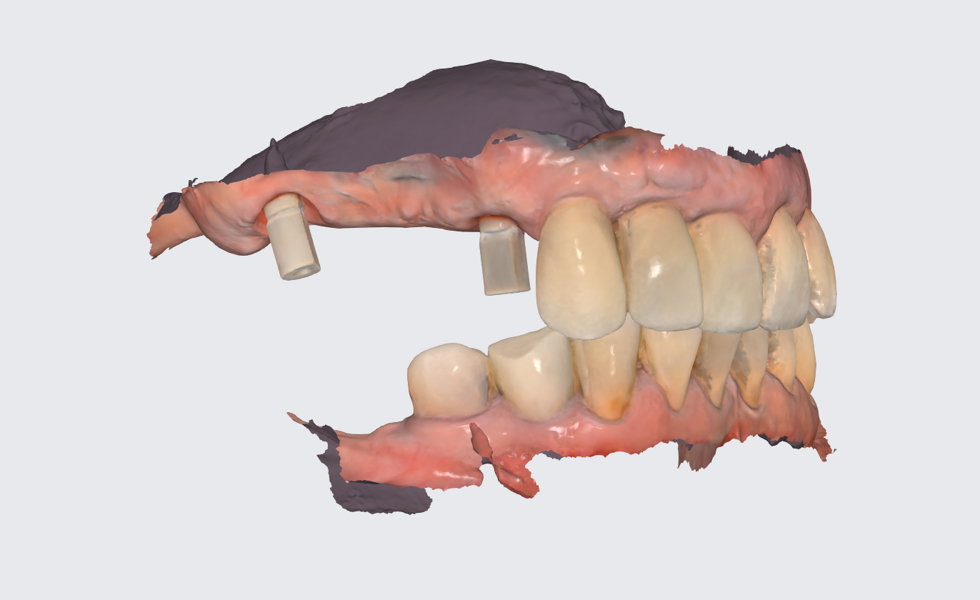

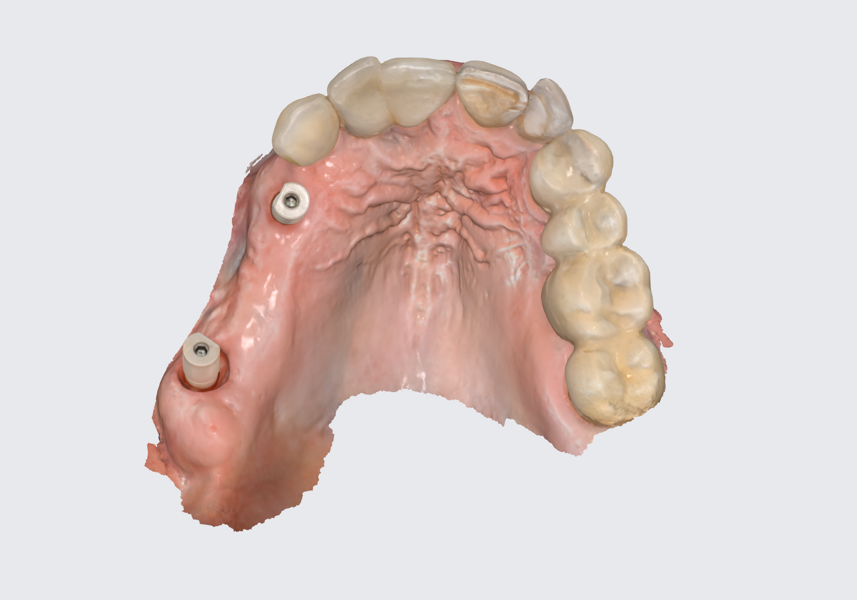

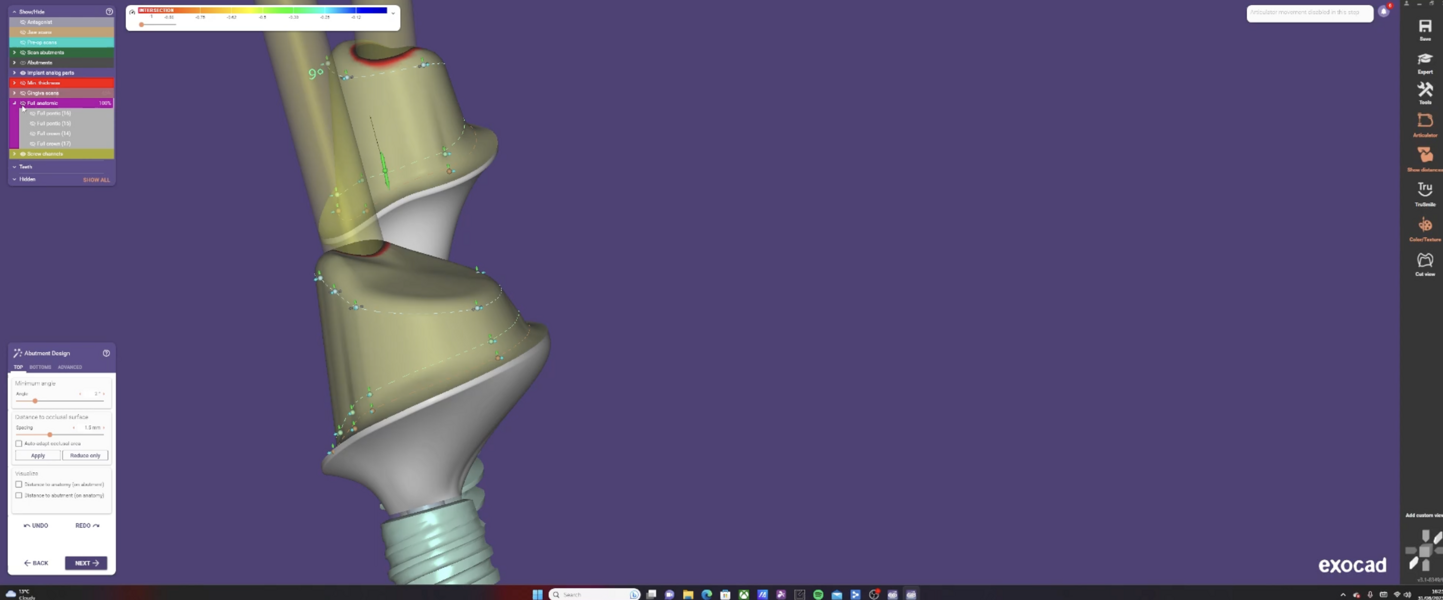

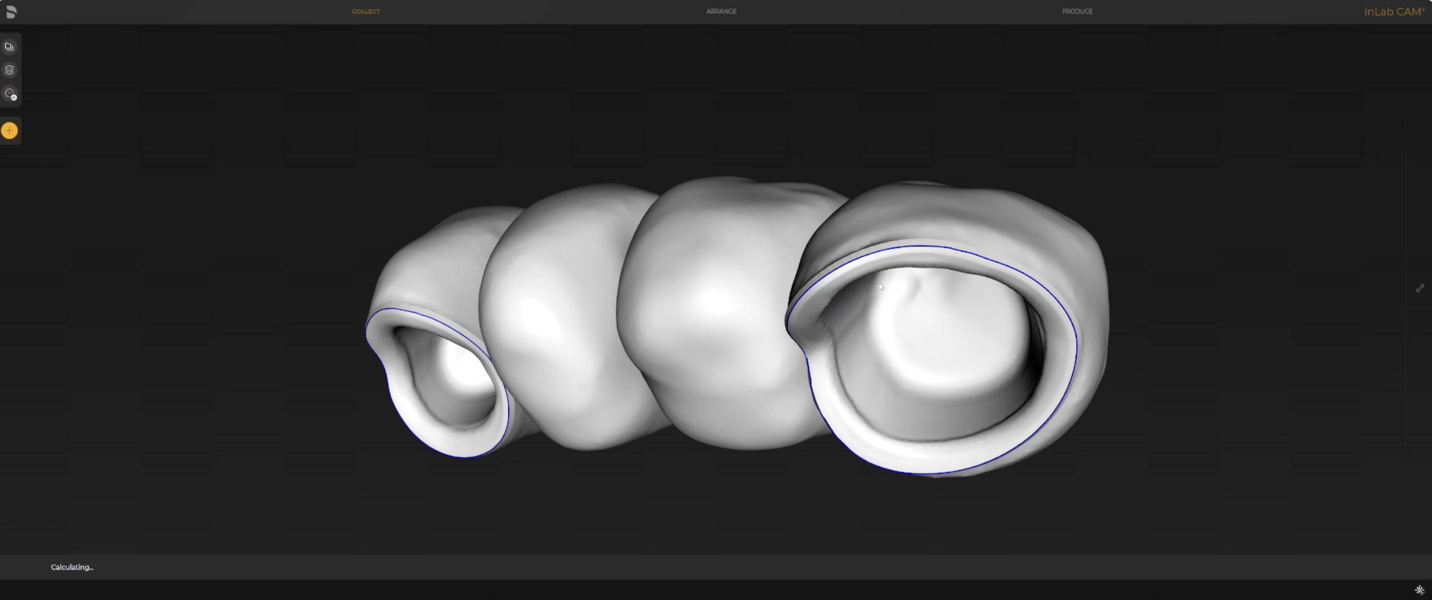

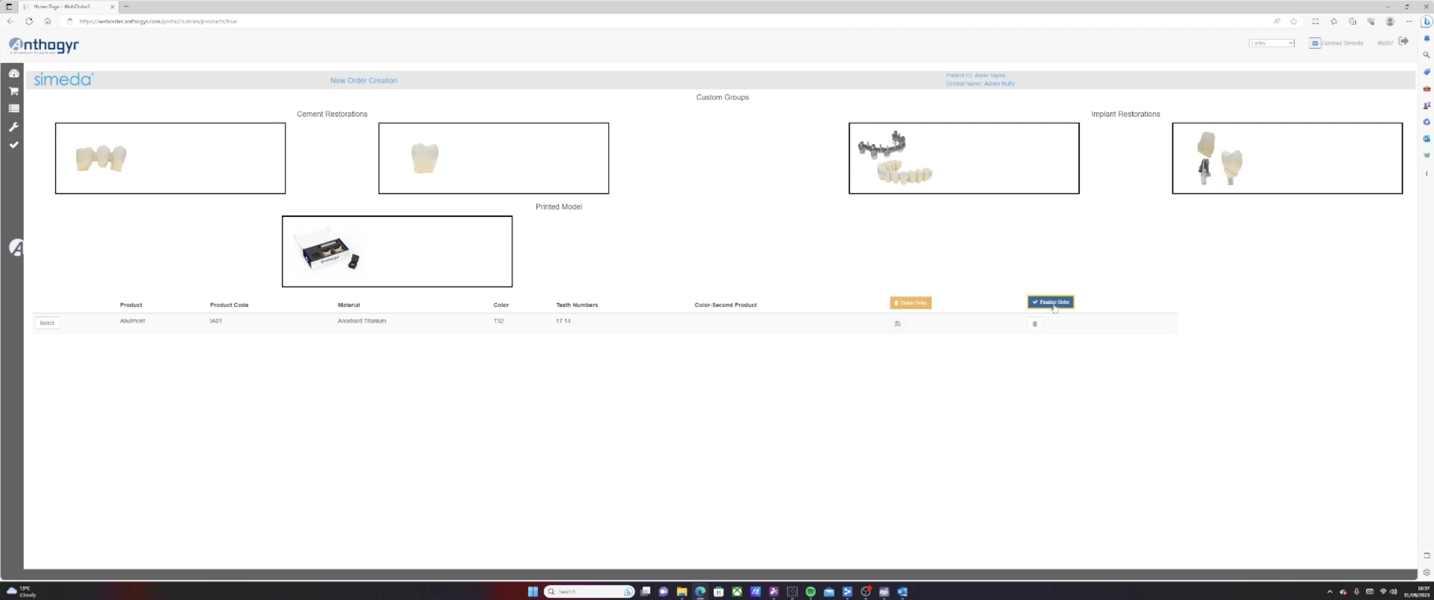

Digital impressions and in-house milling

The Medit i700 scanner was instrumental in obtaining accurate digital impressions. According to Nulty, the trueness and precision of digital scanners, including the Medit i700, are remarkable, ensuring that the final prosthesis fits perfectly.3 Furthermore, in-house milling, as done in this case, provides the clinician with greater control over the design and fit of the final prosthesis, leading to improved patient satisfaction.4

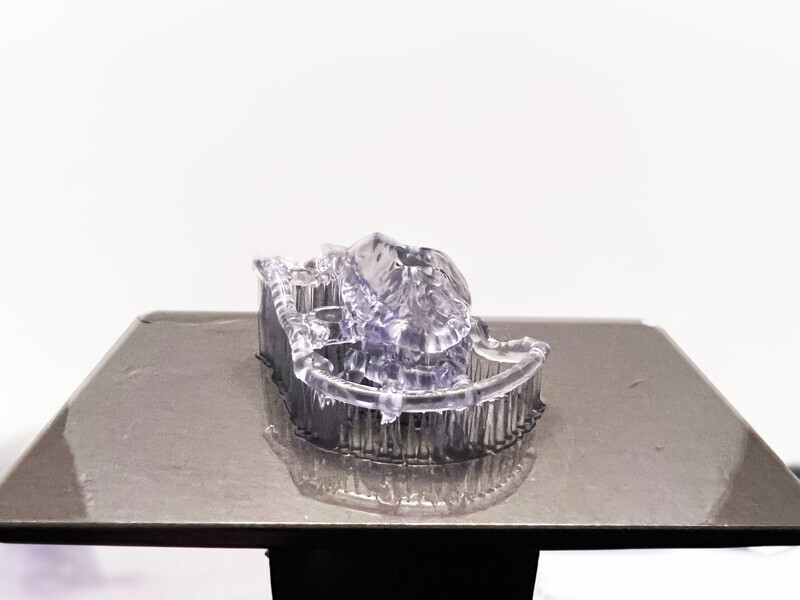

3D printing and accuracy

Nulty compared the trueness and precision of various 3D printers, including the MAX UV, and found them to be highly accurate.5 The MAX UV was statistically superior to the others, having an overall trueness of under 35 μm, ensuring that the printed surgical guides fit precisely during surgery.5 The accuracy of such printers is crucial in ensuring that the surgical guide aligns perfectly with the patient’s anatomy, supporting successful implant placement.

Material selection

The choice of bovine xenograft for socket augmentation is supported by studies that have shown its efficacy in preserving alveolar ridge dimensions after extraction.6 Additionally, the use of lithium disilicate, known for its excellent aesthetic properties and durability, for the final bridge aligns with the current trend in restorative dentistry.7

Collaborative approach

Collaboration between different digital tools, materials and experts, as seen in this case, is a testament to the multidisciplinary nature of modern dentistry. Such an approach ensures that patients receive the best possible care, combining expertise from various domains.

Primary stability and implant design

One of the critical aspects of successful dental implant placement is achieving excellent primary stability. Primary stability refers to the mechanical stability of an implant immediately after placement, and it is a crucial factor in determining the success of osseointegration and the overall outcome of the implant procedure. The Axiom X3 implant, having a unique design, has been recognised for providing exceptional primary stability. Primary stability ensures that the implant securely anchors in the bone, reducing micro-movements that can hinder the osseointegration process. This stability is not just beneficial for the immediate postoperative period but also plays a pivotal role in the long-term success of the implant.8

Conclusion

Digital dentistry, when used comprehensively, can offer patients a swift and precise treatment plan, leading to predictable outcomes. This case serves as a testament to the advancements in the field and their practical applications.

In conclusion, the advancements in digital dentistry, as demonstrated in this case, offer a holistic approach to patient care. By integrating various digital tools and techniques, clinicians can achieve predictable, efficient and aesthetically pleasing outcomes.

Austria / Österreich

Austria / Österreich

Bosnia and Herzegovina / Босна и Херцеговина

Bosnia and Herzegovina / Босна и Херцеговина

Bulgaria / България

Bulgaria / България

Croatia / Hrvatska

Croatia / Hrvatska

Czech Republic & Slovakia / Česká republika & Slovensko

Czech Republic & Slovakia / Česká republika & Slovensko

France / France

France / France

Germany / Deutschland

Germany / Deutschland

Greece / ΕΛΛΑΔΑ

Greece / ΕΛΛΑΔΑ

Hungary / Hungary

Hungary / Hungary

Italy / Italia

Italy / Italia

Netherlands / Nederland

Netherlands / Nederland

Nordic / Nordic

Nordic / Nordic

Poland / Polska

Poland / Polska

Portugal / Portugal

Portugal / Portugal

Romania & Moldova / România & Moldova

Romania & Moldova / România & Moldova

Slovenia / Slovenija

Slovenia / Slovenija

Serbia & Montenegro / Србија и Црна Гора

Serbia & Montenegro / Србија и Црна Гора

Spain / España

Spain / España

Switzerland / Schweiz

Switzerland / Schweiz

Turkey / Türkiye

Turkey / Türkiye

UK & Ireland / UK & Ireland

UK & Ireland / UK & Ireland

International / International

International / International

Brazil / Brasil

Brazil / Brasil

Canada / Canada

Canada / Canada

Latin America / Latinoamérica

Latin America / Latinoamérica

USA / USA

USA / USA

China / 中国

China / 中国

India / भारत गणराज्य

India / भारत गणराज्य

Pakistan / Pākistān

Pakistan / Pākistān

Vietnam / Việt Nam

Vietnam / Việt Nam

ASEAN / ASEAN

ASEAN / ASEAN

Israel / מְדִינַת יִשְׂרָאֵל

Israel / מְדִינַת יִשְׂרָאֵל

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Algeria, Morocco & Tunisia / الجزائر والمغرب وتونس

Middle East / Middle East

Middle East / Middle East

To post a reply please login or register